News

In modern packaging lines, managing products of various weights efficiently is essential. A weighing print and apply labeling machine integrates weighing, printing, labeling, and sorting in one system. It automatically detects product weight, prints matching labels, and sorts products by category — improving both speed and accuracy.

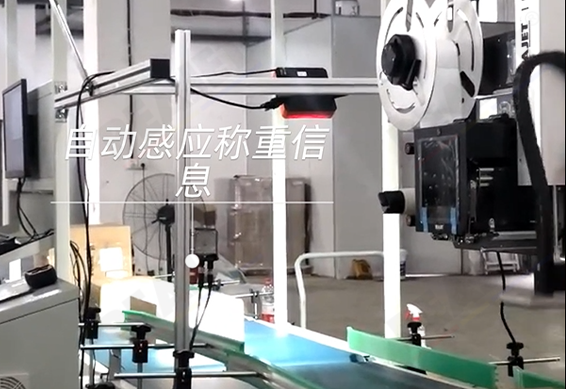

1. Real-Time Weighing and Data Feedback

The system uses precision sensors to capture product weight instantly as items move along the conveyor.

Millisecond-level weighing response;

Automatic data filtering and calibration;

Label content directly linked with weight data.

This ensures every product weight is recorded accurately.

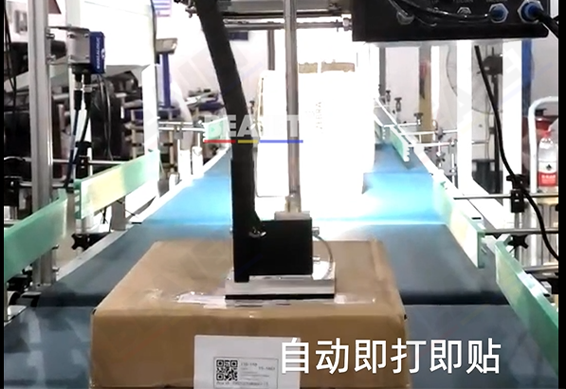

2. Instant Printing and Label Synchronization

After weighing, the machine immediately prints the corresponding label and applies it in the same motion.

Labels include net weight, batch number, or traceability code;

Printing and application happen simultaneously;

Maintains consistent label position and accuracy.

Guarantees labeling precision without slowing down the line.

3. Automatic Sorting and Classification

Once labeled, products are automatically sorted into the correct output lanes based on preset weight ranges.

Multi-level sorting channels supported;

Compatible with roller or belt conveyors;

Automatically removes out-of-range items.

Reduces manual sorting workload and ensures reliable classification.

4. Enhancing Line Efficiency and Traceability

By integrating weighing and labeling, the system builds a closed-loop traceability process.

Minimizes manual handling;

Ensures consistent labeling and shipment accuracy;

Enables statistical and quality data tracking.

A key upgrade for modern packaging and distribution centers.

The weighing print and apply labeling machine combines weighing, labeling, and sorting to create an efficient and traceable packaging process. For more details or customized system integration, contact Hangzhou Beajet Digital Technology Co., Ltd., your trusted partner in intelligent labeling and automation solutions.