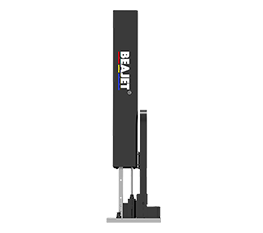

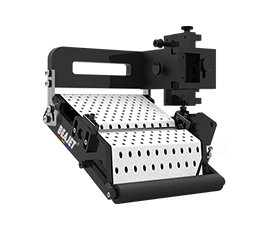

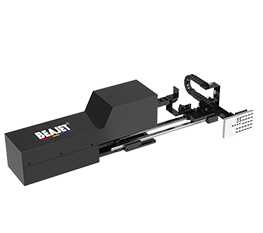

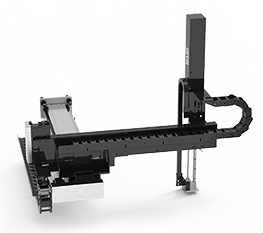

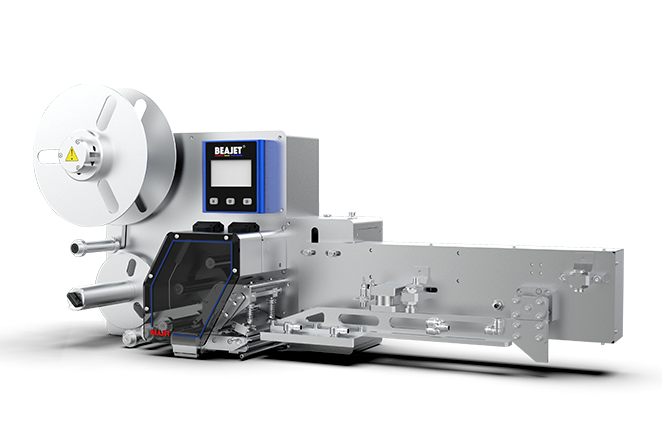

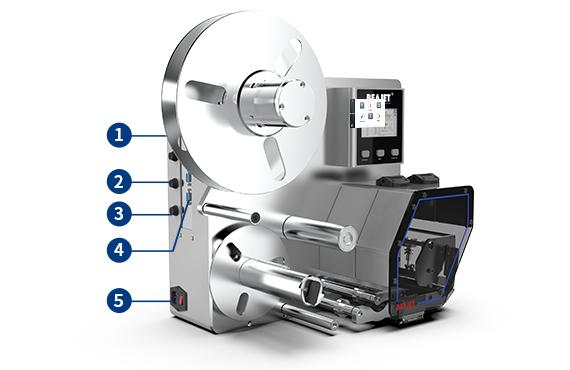

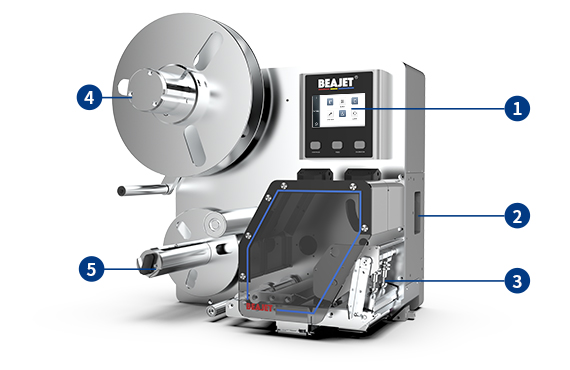

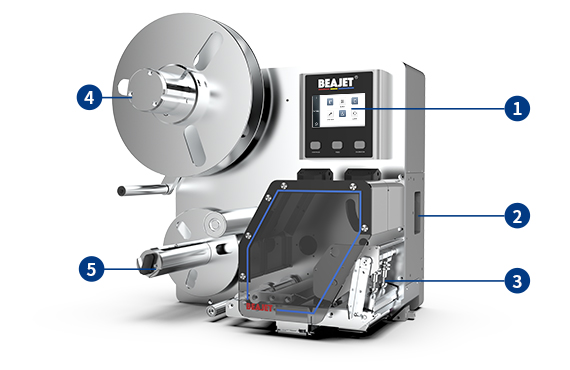

| 1 Touch screen:: Multifunctional touch screen: Integrated print module control and printer control of all Settings 2 Label arm fixed position: The standardized labeling fixed position can realize the same host with different labeling arms to achieve different labeling functions and labeling requirements 3 Printing module: Fully self-developed printing module can stably realize the label heat transfer printing with a width of 8-110mm 4 Discharge tray: Inner diameter 76mm, maximum label diameter 300mm 5 Material receiving tray: The tensioning force of the receiving tray can be adjusted freely to achieve more stable bidding and winding |

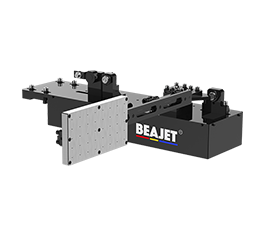

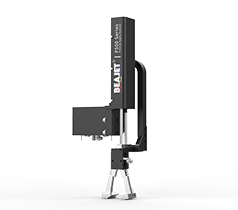

1 Ethernet port: 10/100 Mbit/s,High stability, long transmission distance 2 4PINinterface: Active interface, up to two sensors can be connected 3 9PINinterface: Interworking with external devices through I/O points 4 A serial port: RS485 serial port 5 The power supply:

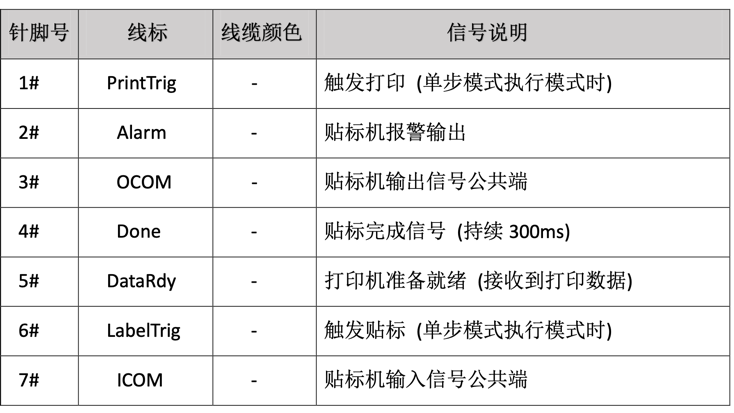

7pinPort Description: |

|

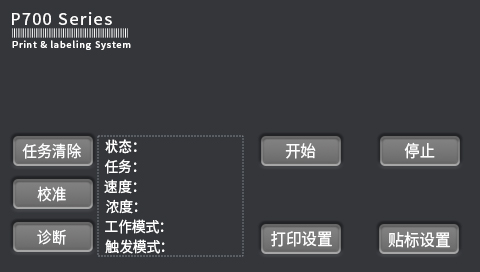

| Start Menu:Displays device status, task status, print speed, concentration, working mode and trigger mode. In the Status bar:Show whether the current device is running normally, if it is not usually specific equipment alarm content. Task Status:You can determine if there is now a print task on the device. |

|

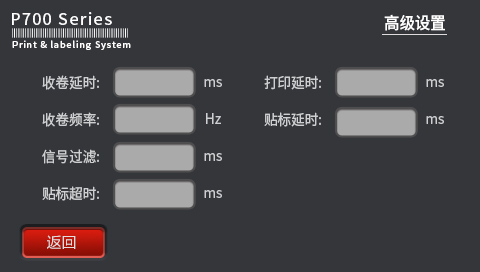

According to the different label size and material and labeling requirements, set different parameters to improve the printing and labeling stability. Now many devices on the market are more curing can not set winding delay and winding frequency -- As a result, the equipment is not ideal for label printing and labeling of special materials and sizes |

|

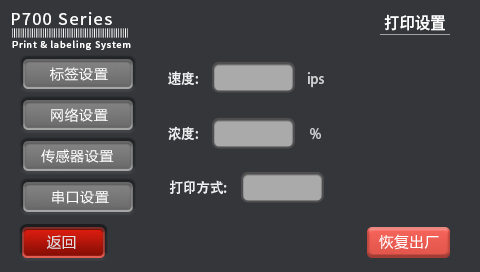

With simple print Settings, you can make label printing much clearer. By switching between different printing modes, labels of different materials can be printed. |

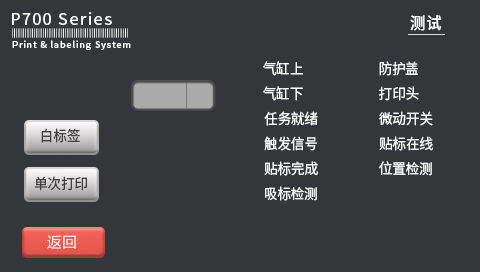

| Through the test mode, it can quickly test the acceptance of equipment on business trip. Simple tests can also determine whether the device is internally or externally driven. |

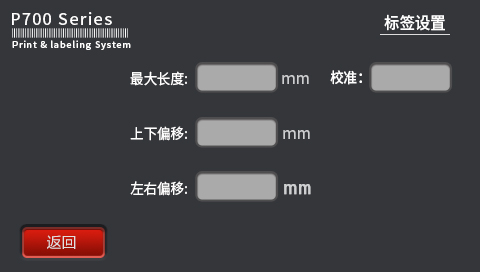

| By setting the label size and offset, the device automatically sets required printing and labeling parameters. To achieve the purpose of fast normal operation of the equipment |

| 1 Touch screen:: Multifunctional touch screen: Integrated print module control and printer control of all Settings 2 Label arm fixed position: The standardized labeling fixed position can realize the same host with different labeling arms to achieve different labeling functions and labeling requirements 3 Printing module: Fully self-developed printing module can stably realize the label heat transfer printing with a width of 8-110mm 4 Discharge tray: Inner diameter 76mm, maximum label diameter 300mm 5 Material receiving tray: The tensioning force of the receiving tray can be adjusted freely to achieve more stable bidding and winding |

1 Ethernet port: 10/100 Mbit/s,High stability, long transmission distance 2 4PINinterface: Active interface, up to two sensors can be connected 3 9PINinterface: Interworking with external devices through I/O points 4 A serial port: RS485 serial port 5 The power supply:

7pinPort Description: |

|

| Start Menu:Displays device status, task status, print speed, concentration, working mode and trigger mode. In the Status bar:Show whether the current device is running normally, if it is not usually specific equipment alarm content. Task Status:You can determine if there is now a print task on the device. |

|

According to the different label size and material and labeling requirements, set different parameters to improve the printing and labeling stability. Now many devices on the market are more curing can not set winding delay and winding frequency -- As a result, the equipment is not ideal for label printing and labeling of special materials and sizes |

|

With simple print Settings, you can make label printing much clearer. By switching between different printing modes, labels of different materials can be printed. |

| Through the test mode, it can quickly test the acceptance of equipment on business trip. Simple tests can also determine whether the device is internally or externally driven. |

| By setting the label size and offset, the device automatically sets required printing and labeling parameters. To achieve the purpose of fast normal operation of the equipment |

| Brand Name: | BEAJET |

| Printing Resolution: | 203dpi、300dpi、600dpi |

| Label Material: | Coated paper、thermal paper、PE composite membrane and so on |

| Label Size: | W:8-110mm、H:10-300mm |

| Label Roll Size: | Inner diamater: 76mm,Outer diamater: 300mm |

| Power Supply: | 100-220V |

| Work Pressure: | 0.4-0.6Mpa |

| Interface Type: | USB、Ethernet |

| Control Interface: | 2PIN RS485、4PIN Active Interface、9PIN IO Point |

| storage: | Flash flash 32MB, Sdram128MB |

| Warranty: | 1 Year |

| Print Head Warranty: | 3 months or 30KM |