News

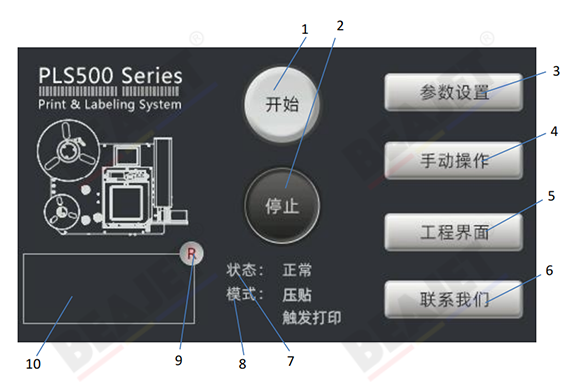

In automated production lines, parameter overwrites in print and apply machines are often difficult to detect. The machine may continue running normally while using incorrect settings, leading to accumulated labeling errors.

1. Detect Subtle Changes in Labeling Results

Parameter overwrites usually cause slight but consistent deviations:

Labels shift by a fixed distance

Print position drifts without mechanical adjustment

Occasional misalignment within the same batch

These signs often indicate overwritten parameters.

2. Compare Parameters Before and During Operation

Overwrites may occur after power cycles or job changes. Key actions include:

Saving standard parameter profiles

Comparing critical settings before and after operation

Focusing on print offset, trigger delay, and label position

Unexpected changes strongly suggest parameter overwriting.

3. Check for Repetitive Error Patterns

Parameter-related issues tend to be consistent:

Identical deviation on every product

Errors disappear after restart and reappear later

Issues occur immediately after job switching

Such patterns are rarely caused by mechanical faults.

4. Review External System Data Writes

Some parameters may be overwritten by external systems:

Automatic recipe or job loading

Shared parameter templates across stations

Unrestricted remote write permissions

External data input is a common hidden cause.

Hidden parameter overwrites pose significant risks despite being difficult to notice. Early identification is essential to avoid large-scale labeling issues. If on-site diagnosis is challenging, professional support is recommended. Hangzhou Beajet Digital Technology Co., Ltd. specializes in print and apply machines and integrated solutions, providing targeted technical support for complex production environments.