News

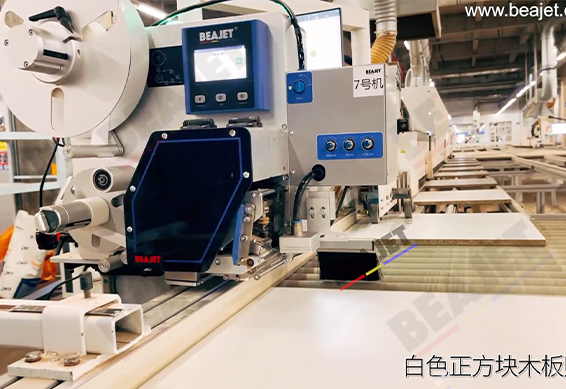

In manual or semi-automatic labeling processes, operators constantly decide which label to use, where to apply it, and whether it is correct. These judgment points are major sources of labeling errors. Print and apply labeling machines shift decision-making from people to systems.

1. From Manual Label Selection to System-Driven Data

In automated labeling workflows:

Label data is sent directly from ERP, MES, or WMS

Printing and application are triggered by production signals

Operators no longer choose label versions manually

This greatly reduces the risk of using incorrect labels.

2. Label Placement Controlled by Mechanisms and Parameters

Instead of relying on visual judgment, machines use:

Fixed reference points

Mechanical guides and stops

Parameterized label position settings

This converts subjective decisions into repeatable mechanical actions.

3. Rule-Based Templates Reduce Complexity

Labeling machines typically use predefined templates:

Each product corresponds to a specific template

Layout, fonts, and barcode rules are preset

Project changes only affect data, not logic

Operators focus on confirmation rather than judgment.

4. System Alerts Replace Manual Error Detection

In manual workflows, errors are often found too late. Automated systems provide:

Missing data checks

Print and apply failure alarms

Integration with scanners or vision systems

Judgment is shifted upstream, reducing inspection burden.

5. Scenarios with the Greatest Impact

The reduction in manual judgment is most noticeable in:

Multi-SKU or multi-project production

Frequent label changes

High-volume or time-critical shipping

Industries with zero tolerance for mislabeling

In these cases, automation improves both reliability and control.

If your process involves many manual judgment points, consult the manufacturer’s technical team before implementation. Hangzhou Beajet Digital Technology Co., Ltd. typically identifies these decision points first and optimizes them through system integration and equipment configuration to reduce human-related risks.