News

In short-term packaging projects such as promotions, seasonal campaigns, and channel-specific releases, label content often changes frequently. Examples include campaign codes, channel marks, batch numbers, and temporary notices.

These scenarios are defined by frequent changes, multiple versions, and short lifecycle labels. Print and apply labeling machines operate here mainly through basic technical workflow control rather than extreme production speed.

Below is a practical, process-level explanation.

1️⃣ Template-based label switching

Short campaign labels are usually managed with fixed templates plus variable fields.

Typical setup:

Multiple label templates created

Each campaign uses one template

Layout remains fixed

Variable fields are reserved

Operators switch templates

Through HMI or software menu

Technically, this is simply loading different label format files, not redesigning labels each time.

2️⃣ Variable field replacement

Most campaign label changes affect only certain fields:

Campaign codes

Channel IDs

Dates and batches

Serial numbers

QR contents

Print and apply systems support variable data printing. Data sources usually include:

Host system data

Scanner input

Manual entry

Only defined fields are replaced while layout stays unchanged.

3️⃣ Trigger-based printing control

Short campaign packaging often requires print-after-confirmation logic. Common triggers include:

Scan-to-print

Weighing signal

Button confirmation

Order signal from system

Technically this is signal-triggered printing:

Signal present → print

No signal → wait

This prevents unused labels from being printed in advance.

4️⃣ Basic queue and cache handling

Label order problems can appear in small mixed batches. Most systems use simple print queues:

Data enters queue in order

Labels print in order

Cache can be cleared if needed

Typical operator actions before switching campaign versions:

Clear buffer

Reload template

Print one test label

This is standard operating procedure rather than advanced control logic.

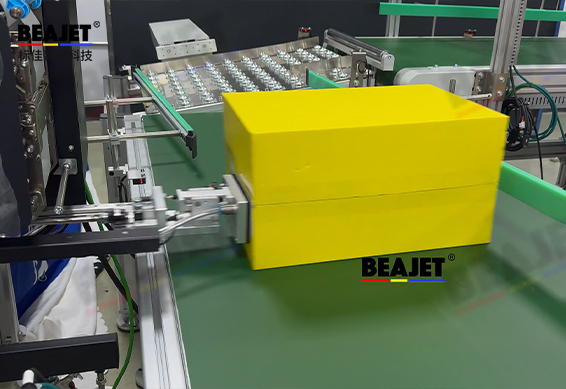

5️⃣ Mechanical adjustment for different packages

Short campaigns may involve different package types:

Cartons

Color boxes

Poly bags

Wrapped packs

Machines adapt mainly through basic adjustments:

Height adjustment

Apply angle adjustment

Switching tamp/blow/roll modes

These are mechanical and parameter adjustments, not complex modifications.

6️⃣ Common on-site switching workflow

Typical switching steps in campaign packaging:

Select template

Update variable rules

Clear print buffer

Print test label

Run small trial batch

Start full run

This is primarily workflow discipline, not high technical complexity.

In short-term campaign packaging, print and apply labeling machines function through template control, variable data replacement, trigger logic, and basic mechanical adjustment.

In real deployments, Hangzhou Beajet Digital Technology Co., Ltd. systems are usually configured around these basic mechanisms so operators can complete campaign label switching using standard operating steps.